A CNC machine has many parts. These include electrical and mechanical. Electrical parts typically can include a computer, breakout board, motors, power supply unit (PSU) and limit switches. The computer will send directions to the breakout board, and the board will run the motor that controls the spindles. CNC machines use binary numbers (0,1) to signal motors. This allows the machine to start and stop. The power supply unit runs the supply to the motor which creates designs. The limit switches will allow your machine to know when and where to stop. The mechanical aspects of a CNC machine, are the frame, transmission, bearings, couplers, and guides/supports. The frame holds the machine, and allows the transmission to transfer movement of the motors to the axis. CNC machines can have two or more directions of axis. The first one is liner driven along straight paths (horizontal) and the other is rotary- driven in a circular path. The rotary axis create contours, curves and semicircles. Bearings keep the spindle up right and reduce strains on the spindle. The guides keep the machine steady and guides the linear movement. The goal of any user beginning in CNC should be the understanding of the basic machining practices of operating the CNC machine tool. The four basic areas a programmer should concentrate on are:

• Understand the machine’s basic components.

• Know the machine’s directions of motion or axes.

• Familiarize yourself with any machine equipped accessories.

• Find out what programmable functions are included with the machine and learn how they are programmed.

This article helps you learn more about each CNC function as it applies to your CNC machine(s). It explains how and why it functions the way it does and shows you how to adapt with any style of CNC machine tool.

CNC FUNDAMENTALS

CNC equipment offers important benefits. Improved automation has dramatically cut down the need for a machine operator and CNC’s can run unattended during an entire machining cycle, freeing the operator for other tasks. CNC’s today are unbelievably accurate, especially in repeatability specifications. The flexibility of a CNC can run a variety of different programs and have work pieces leading to fast changeovers and set ups. Motion control is the basic function of any CNC machine. All forms of CNC equipment have 2 or more directions of motion called axes. There are 2 axis types:

1. Lineardriven along a straight path.

2. Rotary- driven along a circular path. On a linear axis , the number of revolutions of the axis drive motor precisely controls the amount of linear motion along the axis and it’s very precise. CNC machines allow motions to be actuated by servomotors instead of turning cranks and handwheels of the past.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

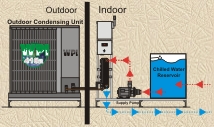

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |